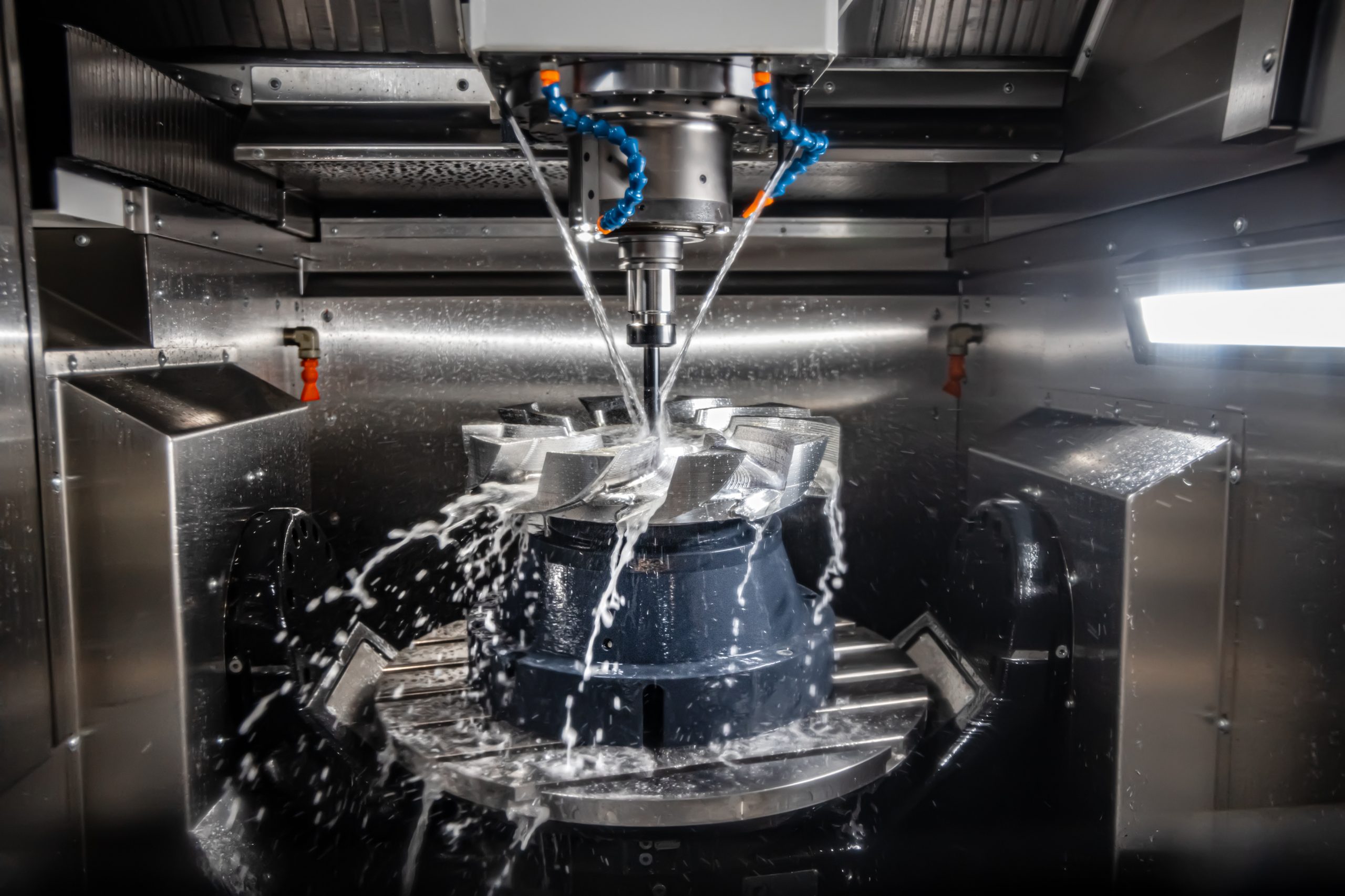

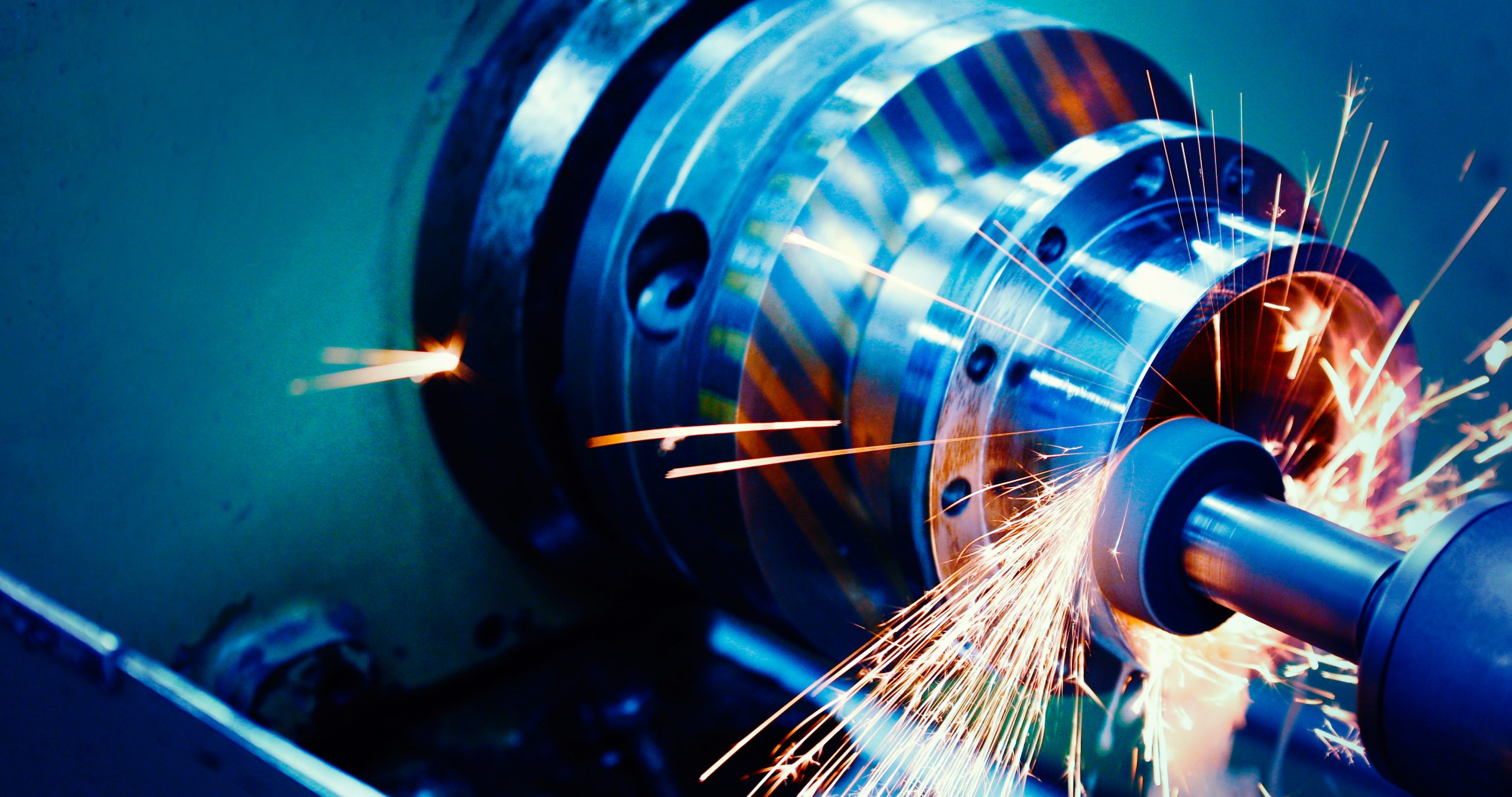

NEW CNC MILLING, TURNING, & GRINDING MACHINES

With over 50 years’ experience in supplying World Class Machine Tools, RBR provides proven for your Manufacturing needs.

About

About Us

For 38 years, RBR Machine Tools in Darien, IL has represented a full line of CNC Machine Tools. Grinding, Turning, Milling, or Drilling; whatever your need may be, we have the right machine tool for you.

© 2025 RBR Machine Tools. All rights reserved.